It feels like a year like no other, but it’s not. There’ve been years in the past where Mother Nature has made it difficult to get the crop in the bin in the past. Harvesting in spring is not unheard-of, not common, but not unheard-of.

Getting grain dry enough for storage is just one of the major headaches this year. Keeping it in condition throughout the winter will be another.

“The key to the successful storage of grain over the winter is a function of grain moisture content and temperature,” says John Ippolito, regional crop specialist with Saskatchewan Agriculture. “Getting the grain mass temperature down to between 0 and 50C is critical.” Grain temperatures can be reduced by bin aeration or turning the grain. The primary reason grain goes out of condition in storage is as a result of improper or poor control of temperature which causes moisture to move from one part of the bin and accumulate in others.

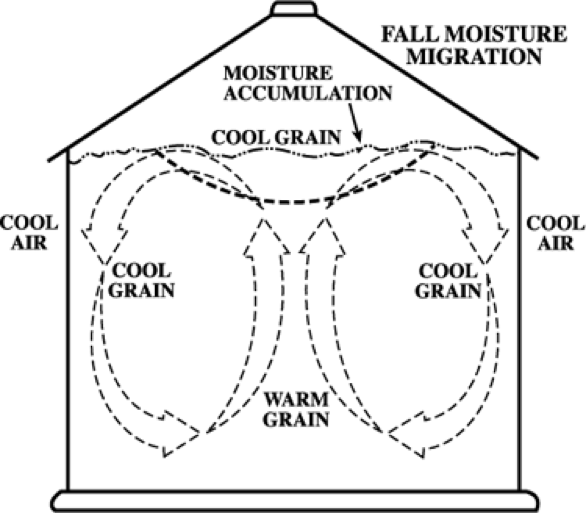

“Whether your grain is dry or not, a key management strategy for binned grain will be to achieve a uniform temperature throughout the bin,” says Ippolito. “Moisture tends to migrate, and this needs to be mitigated to prevent build up – usually in the cone area of the bin.” A grain bin can be envisioned as a tiny climate zone of its own. Air will move down the sides of the bin where it is cooler and rise up the middle where the grain is warmer. This is best understood visually.

“Guys sometimes think the colder the grain, the better,” Ippolito goes on to say. “However, there’s no additional benefit to getting the grain any lower than -50C. Zero is the goal; however, going from 50C to zero is not that difficult using aeration and ambient temperatures.”

The dry, cooled grain in bins should be monitored closely. “Normally, monthly monitoring of grain is sufficient. However, this year has been anything but normal, and to protect your investment until it’s sold and shipped, I am strongly encouraging stepping up to weekly monitoring. Tough grain should be even more closely watched.” Sophisticated in-bin monitoring cables with wireless connections or old-school thermometers on probes all work to accomplish the same goal. However, visual inspection of the bins and the grain is required, as well.

“Most of the mold and insect infestations that can occur in stored grain will usually happen in the cone part of the bin – where moisture typically will migrate to,” says Ippolito. “This is a key area to keep tabs on over the winter.” However, that said, if the grain temperature is consistently at the recommended temperature throughout the grain mass, this will prevent mold growth or insect development.

If the bin is not uniformly cool, expect to find problems within two to three months. When checking bins, look for crusting, wet or slimy grain and any ice or frost accumulations. Check bins before the winter sun warms the roof and look for condensation, a sure sign of moisture migration and possible issues with the grain in the bin. Take grain samples to check for insects as well as examine the grain for off-odors or other signs of mold growth.

If grain spoilage, insects, or moisture build-ups are detected early enough, remedial actions can be taken to prevent the problem from escalating. At worst, selling slightly spoiled or damaged grain, even at a low price, is a better deal than losing a bin altogether.

At all times, take safety precautions when checking bins. Work with a partner. Use safety ropes and respirators when necessary. Never enter a bin when grain is moving. Be cautious of walking on any surface crust. Be alert to the dangers of working with grain that has gone out of condition – inhaling dust and molds can be detrimental to your health.

Leave A Comment